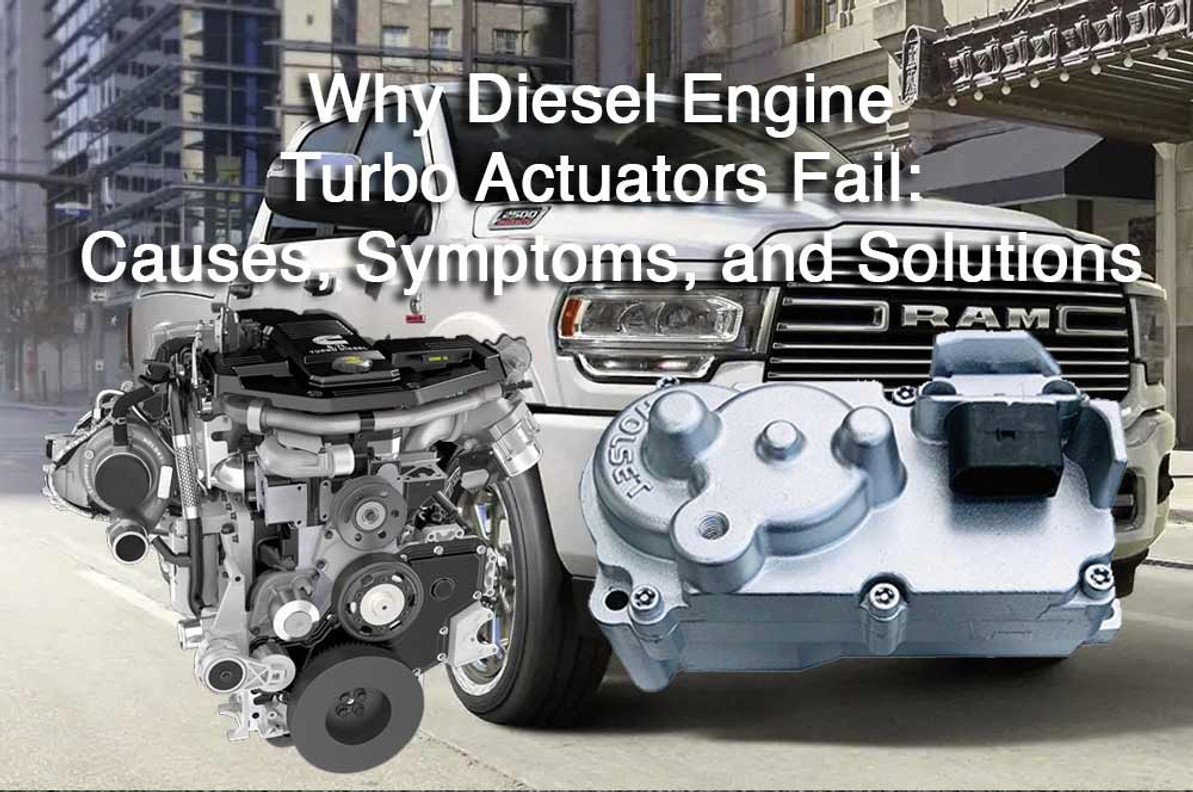

Why Diesel Engine Turbo Actuators Fail: Causes, Symptoms, and Solutions

Introduction:

Diesel engines are known for their power, efficiency, and reliability. However, like any complex machine, they can be prone to faults and failures. One common issue that can affect diesel engines is turbo actuator failure. In this article, we'll explore the causes, symptoms, and solutions for diesel engine turbo actuator failure.

What is a Turbo Actuator?

A turbo actuator is a critical component of a diesel engine's turbocharging system. Its primary function is to control the flow of exhaust gases into the turbocharger, which in turn drives the turbine and compresses the air entering the engine's cylinders. The turbo actuator is typically a pneumatic or electronic device that responds to signals from the engine's control unit to adjust the turbocharger's boost pressure.

Causes of Turbo Actuator Failure:

There are several reasons why a diesel engine turbo actuator may fail. Some of the most common causes include:

- High mileage: Turbo actuators can wear out over time, especially if the engine has high mileage.

- Poor maintenance: Failure to regularly clean and inspect the turbo actuator can lead to clogging and premature failure.

- High boost pressures: Diesel engines that are tuned to produce high boost pressures can put excessive stress on the turbo actuator.

- Contamination: Diesel engines produce more soot and contaminants than gasoline engines, which can clog the turbo actuator's air passages and cause it to fail.

- Electronic control unit (ECU) faults: Problems with the engine's ECU can cause the turbo actuator to malfunction or fail.

Symptoms of Turbo Actuator Failure:

If the turbo actuator fails, the engine may exhibit several symptoms, including:

- Loss of power: A faulty turbo actuator can cause the engine to lose power and performance.

- Reduced fuel efficiency: A malfunctioning turbo actuator can lead to decreased fuel efficiency and increased emissions.

- Increased engine noise: A failing turbo actuator can cause the engine to produce unusual noises, such as whining or grinding sounds.

- Check Engine Light (CEL): A faulty turbo actuator can trigger the CEL to illuminate on the dashboard.

Solutions for Turbo Actuator Failure:

If the turbo actuator fails, there are several solutions available:

- Replacement: The most common solution is to replace the faulty turbo actuator with a new or remanufactured unit.

- Repair: In some cases, it may be possible to repair the turbo actuator by cleaning or replacing worn or damaged components.

- Upgrades: Upgrading to a high-performance turbo actuator can provide improved engine performance and reliability.

Conclusion:

Diesel engine turbo actuator failure can be a frustrating and costly problem. However, by understanding the causes, symptoms, and solutions, you can take steps to prevent or repair turbo actuator failure and keep your diesel engine running smoothly.

Turbo Actuators: https://vehiclemodule.com/turbo-actuators/

Feb 06, 2025

Recent Posts

-

Understanding FICM Part Number 8972160777 and Interchanges for 2001-2004 Chevy GM Duramax Diesel LB7

If you're looking to replace the Fuel Injection Control Module (FICM) in your 2001-2004 Chevy GM Dur …Apr 29, 2025 -

Troubleshooting and Replacing the 2005 Duramax FICM: A Comprehensive Guide

The Fuel Injection Control Module (FICM) is a critical component of your 2005 Duramax engine, respon …Apr 29, 2025 -

Maximizing Your Ford F150's Performance and Comfort with OEM Remanufactured Modules

As a Ford F-150 owner, you know how important it is to keep your vehicle running smoothly and effici …Apr 29, 2025